Working in the summer on the peat press, in winter on the drawing board

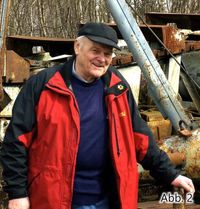

The Erwin Wulfes peat press was built in 1969 to allow peat to be processed on the spot. The processing machine was designed, built and installed by Erwin Wulfes (Fig. 2). In 2012 our founding member and sponsor Erwin Wulfes donated to the society the press, the property, the sum of money deposited with the district council as a guarantee of the obligation to restore the land to its natural state, and additional donations totalling more than € 20,000 to enable us to complete the development of the museum.

The peat was moved under the building in trolleys (Fig. 3) and tipped into a funnel with the aid of a winch. A conveyor belt transported the peat to the mill.

The bucket elevator (Fig. 4) transferred the fine mass into a temporary storage bunker or directly onto a lorry. From here, it was taken for filling in loosely filled sacks. Alternatively, peat bales could be manufactured in a single-shaft press.

Alternatively, peat bales could be manufactured in a single-shaft press. Slats and wire stabilised the bails (Fig. 5) for transport.

In the winter months, peat processing machines were designed and build for clients in Germany, Norway, Finland and Ireland (Figs. 6-8).

Links to other stations in the museum:

<1> <2> <3> <4> <5> <6> <7> <8> <9> <10> <11> <12> <13> <14> <15> <16> <17> <18> <19> <20> <21> <22> <23>